With the continuous development of artillery and as fragmenting artillery projectiles became the norm, fragments propelled by an explosive detonation became the most common cause of injury on the battlefield. During the asymmetric conflicts of the last decades, the widespread use of improvised explosive devices (IEDs)—frequently designed with primary fragmentation in mind and typically generating secondary fragments—has seen the threat of fragmentation damage and injury persist, endangering both personnel and vehicles alike. In order to design armoured protection to resist fragmentation damage, engineers require precise simulation and modelling tools. These allow them to predict the effects of fragmentation on ballistic protection and to generate data to inform future developments. To help with the comparability of threat assessments NATO members agreed during the Cold War to standardise these simulation tools and regulate their usage in a specific testing environment by establishing certain ‘Standardization Agreement’ (STANAG) documents.

Within the NATO testing framework, the two most relevant documents are STANAG 2920, which deals with body armour testing, and STANAG 4164, which validates the protection level of armoured vehicles. In order to keep data consistent and comparable, testing protocols within these documents rely on standardised projectiles. Given the random nature of natural fragmentation (and the wide range of pre-formed fragments which are employed) NATO standardised a set of simulation projectiles for testing. These include a variety of shapes and weights, from right circular cylinders (RCCs) to spheres, cubes, and parallelepipeds. These are propelled against the target to simulate the damage from fragmentation.

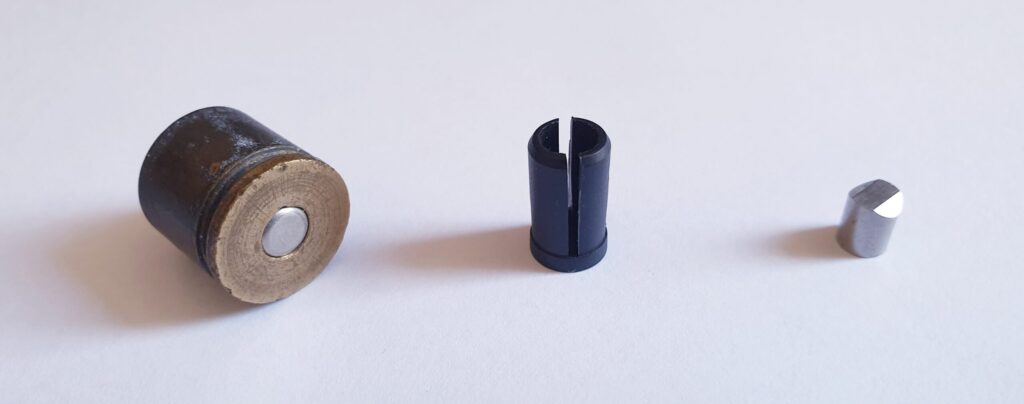

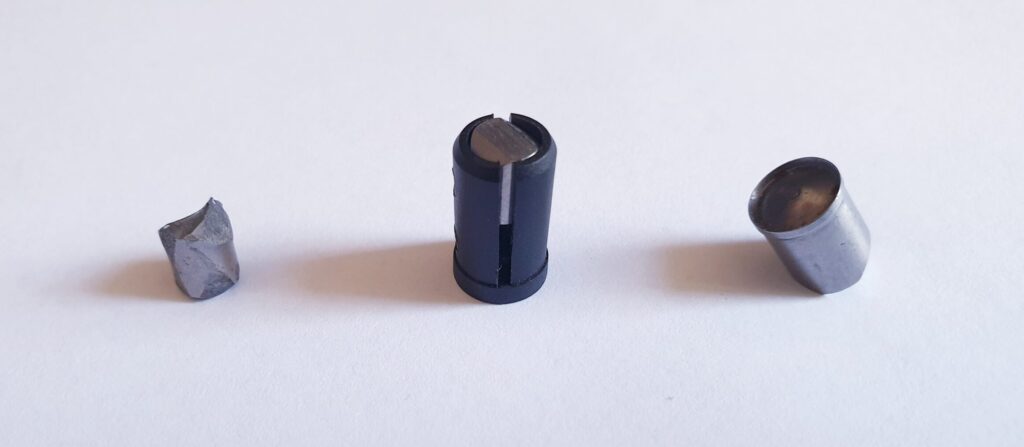

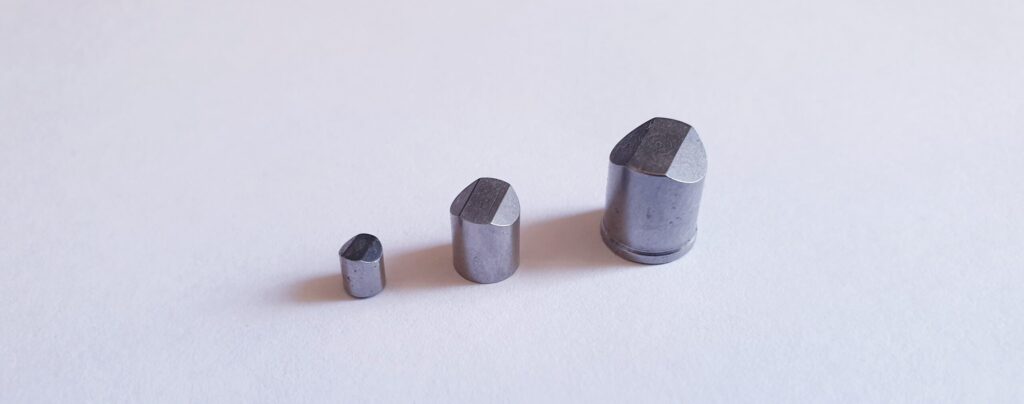

The most common fragment simulator used by NATO is the Fragment Simulating Projectile (FSP). This chisel-nosed cylindrical projectile comes in a variety of calibres, weights, and two basic versions: The so-called ‘F’ version is launched with a sabot, while the ‘G’ version has a slightly modified shape at the base (incorporating a rim) and is launched without a sabot (see Figure 1.2). Otherwise the requirements for every FSP is identical; they should have a smooth surface, all burrs removed, and a hardness value of 32 HRC (with tolerance of +/- 2 HRC).

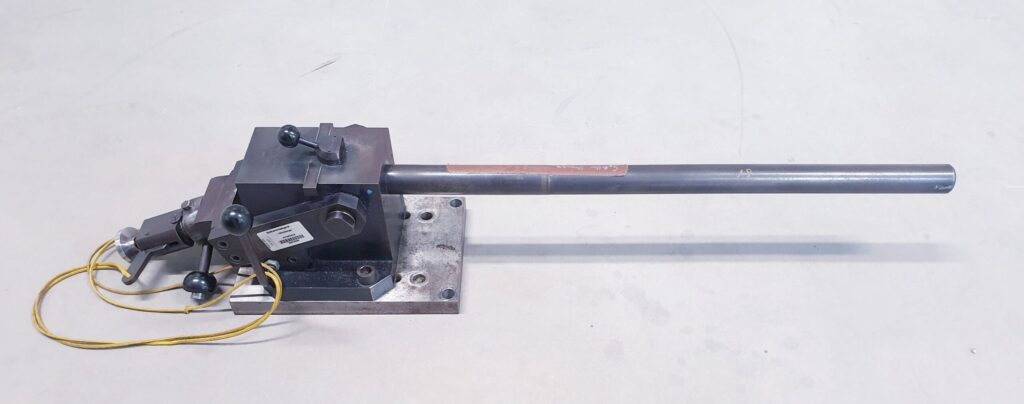

To bring the FSP up to the desired speed, launching device are used that have to be capable of consistently and reproducibly propelling the projectile at the correct velocity to impact the ballistic protection material being tested. These launchers comprise a heavy base with a universal locked breech and interchangeable barrels for different calibres. The breech allows for the loading of the FSP and a primer in a reusable base to ignite the powder charge, the latter achieved either by a striker or electrically. The powder charge has to be carefully adjusted for the desired impact velocity while taking into account parameters like the increasing heat (after firing multiple shots) of the testing barrel and other environmental factors.

Once the FSP is fired against a component the ballistic performance of the item being tested is judged by examination of the armour itself and an aluminium witness plate placed behind it. The damage (or lack thereof) to the witness plate is the final performance indicator for the armour. Its purpose is to simulate the human body and it is examined after every impact. If the aluminium shows penetration by the projectile—or was perforated by target material which impacted it through spalling—it is considered a failure of the armour.

As noted, FSPs are available in multiple calibres and projectile weights. The smallest FSPs, such as the 4 gr (0.26 g) version, are mostly used for the testing of ballistic eyewear. The most common projectile to validate body armour is the 17 gr (1.10 g) FSP launched with a sabot. At the other end of the scale are the large-calibre FSPs, such as a 12.7 mm example which weighs 13.4 g (207 gr) and a 20 mm model which weighs 53.8 g (830 gr). These larger FSPs are used to test the protection level of armoured vehicles according to STANAG 4164. For example, STANAG threat level 6 includes the simulation of a 155 mm shell detonating 10 m away from the armour segment by engaging the armour under testing with a 20 mm FSP at a speed of 960 m/s from a distance of 25 m, which impacts the target with an energy of 24,800 J.

The effectiveness of the STANAG FSP testing methods has been subject to debate. Both the FSP and the aluminium witness plates have been described as not being representative enough to inform specific conclusions. The standardisation of FSPs has, in particular, been criticized for not simulating larger, asymmetrically shaped shrapnel or secondary projectiles. On the other hand, the level of protection required to defeat such slower-moving fragments with a larger surface area is almost always going to be less demanding for any armour put to the test. Despite the existing criticisms, the STANAG FSP is a key tool armour development and testing today, and will most like remain so for the next decade or more.

Sources

NATO (North Atlantic Treaty Organization). 1998. Test Procedures for Armour Perforation Tests of Anti-Armour Ammunition. STANAG 4164. Brussels, Belgium: Military Agency for Standardization, NATO Standardization Office.

NATO (North Atlantic Treaty Organization). 2014. Procedures for Evaluating the Protection Level of Armoured Vehicles – Kinetic Energy and Artillery Threat. AEP 55, vol. 1. Brussels, Belgium: Military Agency for Standardization, NATO Standardization Office.

NATO (North Atlantic Treaty Organization). 2015. Classification of Personal Armour. STANAG 2920. Brussels, Belgium: Military Agency for Standardization, NATO Standardization Office.

Remember, all arms and munitions are dangerous. Treat all firearms as if they are loaded, and all munitions as if they are live, until you have personally confirmed otherwise. If you do not have specialist knowledge, never assume that arms or munitions are safe to handle until they have been inspected by a subject matter specialist. You should not approach, handle, move, operate, or modify arms and munitions unless explicitly trained to do so. If you encounter any unexploded ordnance (UXO) or explosive remnants of war (ERW), always remember the ‘ARMS’ acronym:

AVOID the area

RECORD all relevant information

MARK the area from a safe distance to warn others

SEEK assistance from the relevant authorities

Pingback: Russlands Kampfpanzer T-14 Armata – Daten, Fakten, Mythen – Konflikte & Sicherheit