Note: The information in this article has been superseded by that authored by Jonathan Ferguson & N.R. Jenzen-Jones and published in Jonathan Ferguson’s important original research work, Thorneycroft to SA80: British Bullpup Firearms, 1901–2020. That book is available from the Headstamp Publishing website: https://www.headstamppublishing.com/bullpup-rifle-book

This post accompanies the eleventh in a series of collaborative videos produced with ARES Researcher Ian McCollum, who also runs the Forgotten Weapons blog and YouTube channel. Using access to unique collections facilitated by ARES, this series of videos will examine a range of interesting weapons over the coming months. Each video will be accompanied by a blog post, here on The Hoplite, and supported by high quality reference photographs. – Ed.

Jonathan Ferguson with N.R. Jenzen-Jones

An ‘area effect’ weapon was a requirement from the outset of the SA80 programme, and appeared in wooden mock-up form in the 1970 Preliminary Study (published 1971). General Staff Requirement (GSR) 3518, issued in 1974, notes that the individual weapon was required to “…be able to accept an area target capability for muzzle or tube-launched grenades”. GSR 3518 goes on to note that “[t]he area target capability may be provided by tube-launched or muzzle-launched grenades but will have recoil forces no greater than 80 joules.”

Interestingly, the only existing grenade launcher assessed in early studies was the Colt XM148 launcher, but it appears that no attempt was made to adapt this system for the SA80 prototypes. However, a quite detailed design and mock-up were produced for an Enfield-designed under-barrel grenade launcher (UBGL). In a forward-thinking move, this was designed to pivot out to one side with the press of a lever, permitting the use of cartridges with a greater overall length. The mock-up included a rifled barrel and its mechanism was fabricated from metal, with a support arm running in a track to guide and retain the breech end of the tube as it pivoted outward.

Given equal weight in the study was the alternative or supplement of the traditional muzzle-launched rifle grenade, which was already in limited anti-tank service with the L1A1 Self-Loading Rifle (FN Herstal FAL). The ENERGA high explosive anti-tank (HEAT) rifle grenade, produced by MECAR of Belgium, was formally issued to British forces in 1952 as the ‘Anti-Tank Grenade, No. 94 (ENERGA)’. Early in the SA80 programme, wooden rifle grenade was made that could be slotted into the muzzle of the various mock-up rifles. Unfortunately, this mockup rifle grenade appears to be no longer extant in the former Pattern Room collection. These two solutions, UBGL and rifle grenade, would be investigated in parallel for a number of years.

SA80 programme mock-up with under-barrel grenade launcher. Note munition mock-ups, one with an overall length greater than typical (photo credit: Jonathan Ferguson/ARES).

The fairly elaborate mock-up UBGL design was built into a fully functional weapon and fitted to a single example of the XL64E5 rifle, probably in early 1976. As in the mock-up, the barrel was rifled. No grenade sight appears to have been fitted; if it was, no evidence of it exists today. Similarly, no replacement upper handguard was produced, leaving the gas parts exposed. This XL60 series grenade launcher features an unconventional and not wholly practical trigger mechanism, which surprisingly enough is also present on the mock-up in functional form (that is, it cocks and dry fires). This is located on top of the UBGL, placing it between the barrel of the grenade launcher and the gas block of the host rifle. The front portion is grasped between thumb and forefinger and pulled back against spring tension to cock the weapon. In much the same way as the cocking handle of an open bolt machine gun, it must be manually returned to the forward position. At this point, the cocking slide may be left in the rear position, covering the trigger lever and acting as a safety. In the firing prototype, an additional safety shroud with grasping grooves has been fitted behind the cocking slide. This slides backward to place the weapon in a more positive safe condition. A short lever on the right side acts as the trigger, requiring the firer to either reach over the weapon with their left hand, or to abandon the pistol grip with their right in order to reach forward and fire the weapon.

Technical Specifications: Unnamed XL60 series grenade launcher

Calibre: 40 x 46SR mm

Overall length: 770 mm

Barrel length: 534 mm (21”)

Weight: 3.98 kg (8.8 lbs) [all-up weight on gun with no sights fitted]

Feed device: single-shot

There is no information on any trials that this weapon may have taken part in, and it was not carried forward as the SA80 platform continued to develop. Meanwhile, work continued on the potential rifle grenade. This was initially intended to be launched with a specialist Ballistite-loaded cartridge as the previous No. 94 grenade had been on the L1A1 SLR. This concept was eventually dropped, and a bullet-trap type rifle grenade was sought. The profile of the flash-eliminator (flash suppressor) was designed with an annular grenade-launching flange a short distance behind the slotted ‘bird-cage’ of the muzzle device, which as of the ‘0 series’ guns was provided with a groove and circular spring to properly retain a 22 mm diameter rifle grenade. Sights for the rifle grenade were conceived as auxiliary additions to the improved version of the Sight Unit, Infantry, Trilux (SUIT), soon named the Sight Unit, Small Arms, Trilux (SUSAT). Two experimental solutions were attempted, one pivoting aperture sight graduated from 25 to 125 metres, and another plastic clip-on design with a simple open combat-style sight. The body of the SUSAT was at first machined with an integral dovetail bracket on the side for a more elaborate grenade launching sight, but this feature was not pursued and was eliminated from the design as the SA80 family matured.

In the mid-1980s, as SA80 neared its in-service date, the UBGL concept resurfaced. By this time the US AAI M203 (largely produced by Colt) was well established as an industry standard, and one example was adapted to the bullpup shape of the L85A1. More effort was made this time, with a standard L85 handguard cut away underneath to permit attachment of both launcher and handguard. However, the front mounting point was still a clamshell, bolted-on arrangement as per the first (side-opening) UBGL, making quick detachment impossible. The overall length of the full-size M203 (at that time the only variant available) resulted in the barrel of the grenade launcher protruding a couple of centimetres beyond the flash-suppressor of the rifle. The surviving combination weapon pictured here is lacking any sighting arrangement.

Technical Specifications: Colt M203

Calibre: 40 x 46SR mm

Overall length: 380 mm

Barrel length: 305 mm (12”)

Weight: 1.36 kg (3 lbs)

Feed device: single-shot

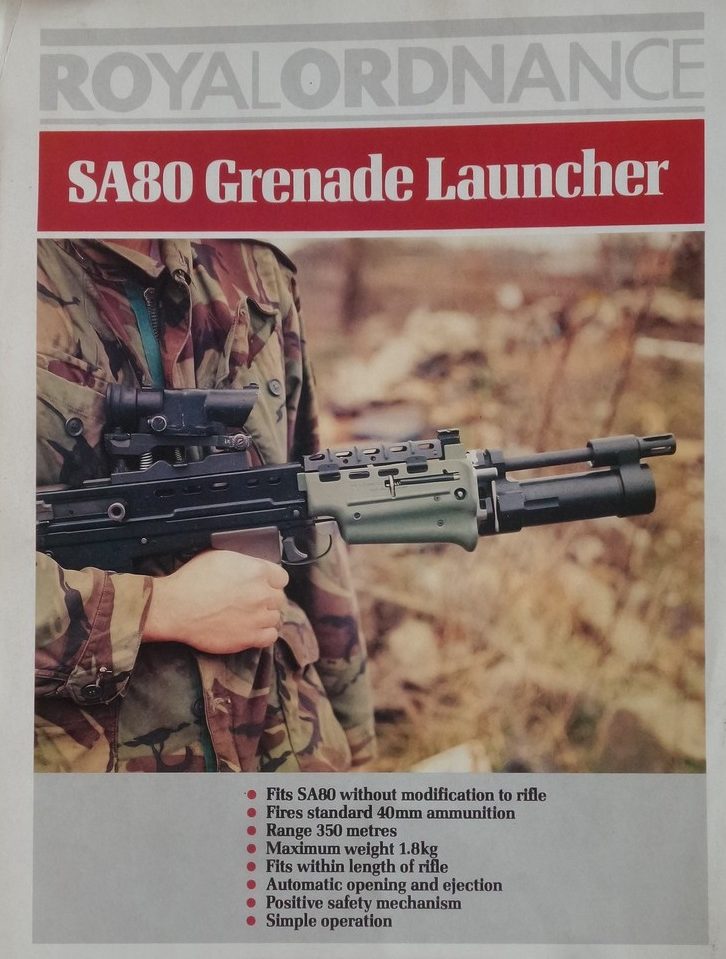

A home-grown offering came in 1988 from Royal Ordnance plc, which threw out its own original side-opening design in favour of what it called the Enfield Close Assault Weapon (ENCAW), allegedly designed in only 20 weeks (see Steve Raw’s, The Last Enfield, p.244). Royal Ordnance offered the weapon for sale simply as the ‘Enfield Grenade Launcher’, and a sales pamphlet gives the range as 350 m and the weight as 1.8 kg, whilst emphasising the weapon’s “automatic opening and ejection” and “positive safety mechanism”.

Technical Specifications: Royal Ordnance ENCAW (Enfield Grenade Launcher)

Calibre: 40 x 46SR mm

Overall length: approx. 340 mm

Barrel length: 175 mm (6.9 ”)

Weight: 1.8 kg (4 lbs)

Feed device: single-shot

The ENCAW was certainly a novel design, the grenade launcher barrel being sleeved over the rifle’s barrel and encased in an enlarged LSW-style handguard, with the release catch at the rear, just above the trigger guard. At the far end, a substantial barrel support bracket held the GL muzzle to the grenade launching ring on the host rifle’s flash-suppressor. This arrangement was enabled by the unique rotating loading mechanism whereby the launch tube pivoted around the rifle barrel to expose the breech. Like a side-opening design, this theoretically allowed the use of grenade cartridges with a greater overall length than would be compatible with a slide-forward breech design. However, due to the compact design, the barrel’s length was dictated by that of the rifle barrel above, resulting in a barrel which would not be compatible with many longer projectiles. The prototype SUSAT on the weapon was furnished with a folding leaf sight after the fashion of the existing US M79 standalone launcher. In this prototype form the launcher was bolted in place around the barrel and onto the front of the Body (upper receiver).

Neither of these designs was apparently satisfactory. Ultimately, the weapon entered service without a UGL, and relied upon the old-fashioned rifle grenade launched from the flash-suppressor with a live round. An optical sight, designed to clip over the front part of the SUSAT was issued under the designation L15A1. At least two other grenade launcher designs were trialled with the SA80 in the late 1980s and early 1990s. The first is a variant of the German Heckler & Koch HK79, which was also seen during testing with the L85A2 during the Future Integrated Soldier Technology (FIST) programme of the early 2000s. A contemporary of the M203, the HK79 has seen limited export success. The variant seen in SA80 trials replaces the host weapon’s handguard, as it does on the G3 and HK33 series of rifles, placing minimal strain on the barrel of the rifle. The HK79 is manually cocked after loading, and the weapon is fired using the support hand (for right-handed users) via a trigger on the left-hand side of the handguard replacement unit. The HK79 uses yet another different loading mechanism from those types examined previously; a drop-breech design results in the barrel pivoting downwards from the point at which it meets the supporting bracket, allowing for longer munitions to be used.

An L85A1 self-loading rifle fitted with a Heckler & Koch HK79 under-barrel grenade launcher (photo credit: original source unknown).

Technical Specifications: Heckler & Koch HK79A1

Calibre: 40 x 46SR mm

Overall length: 357 mm

Barrel length: 297 mm (11.7”)

Weight: 1.67 kg (3.7 lbs)

Feed device: single-shot

A soldier during the FIST trials holding an L85A2 fitted with a Heckler & Koch HK79 under-barrel grenade launcher (photo credit: UK MoD).

The second was the HG40, produced by the Hilton Gun Company, a small, now-defunct British firm based in Derbyshire. A two-piece bracket arrangement clamps over the barrel behind the grenade launching ring on the host rifle’s flash-suppressor. Much like the HK79, the HG40 employs a drop-breech system. The trigger mechanism for the grenade launcher sits almost directly below that of the host weapon. Little else is known about the weapon. The 1991 edition of Jane’s Infantry Weapons gives the statistics below, and indicates that the HG40 was undergoing UK military trials at the time of publication.

Hilton Gun Company HG40 grenade launcher (photo credit: original source unknown)

Hilton Gun Company HG40 grenade launcher (photo credit: original source unknown)

Technical Specifications: Hilton HG40

Calibre: 40 x 46SR mm

Overall length: 388 mm

Barrel length: 310 mm (12.2”)

Weight: 1.5 kg (3.3 lbs)

Feed device: single-shot

In 1995, a decade after the SA80 entered service, Heckler & Koch offered British forces a variant of their AG36 UGL known as AG SA 80. This design has proved to be a popular replacement for the legacy weapons of several nations, including the United States, where it is known as the M320. The AG SA80 was adopted and received the designation L17A2, the parallel A1 variant being an accessory for the L119A1 (Diemaco C8 SFW). The weapon is aluminium in construction with a polymer mount that replaces the host rifle’s handguard. This mount includes a hinged top cover to access the weapon’s gas parts. This includes an integral folding tangent sight mounted on the left side and graduated from 50 m to 350 m. A Picatinny rail strip opposite allows the mounting of the Laser/Light Module (LLM). These also feature a polymer bracket to accommodate the activation switch. The barrel has 6 grooves with a 1:1200 twist. The AG SA 80 features a double-action trigger; the other models are single-action or cock-on close. Comparable with most other 40 x 46SR mm weapons, the L17A2 has an effective range of some 400 m, and develops a muzzle velocity of 76 m/s. The example seen in the video accompanying this post is a developmental iteration of the L17A2 marked simply ‘SA80 GL’. It is installed on an L85A1 rifle, which is not a configuration that ever saw service.

However, the L17A2 was not actually issued until the A2 programme had been completed in 2002, at which point it became the L123 (the current service variant being designated the L123A3). The folding ramp quadrant sight may be removed and replaced with an elevating bracket mount for either the EOTech reflex sight or the RAAM UGL-FCS electro-optical fire control system. Needless to say, this package of rifle, GL and two optical sights is significantly heavier than the base rifle with optic. A more conventional form of the AG36 appeared in 2016 on the prototype L85A3. That weapon’s new rail system enables the much more compact launcher to be fitted directly to the 6 o’clock rail. Given that the new top rail is integral to the new handguard, it seems very likely that this new launcher will replace the L17A2/L123 series in service (the alternative being to continue using legacy rail adaptors for UBGL-equipped rifles).

Technical Specifications: Heckler & Koch AG SA 80 (L17A2 Grenade Launcher)

Calibre: 40 x 46SR mm

Overall length: 348 mm

Barrel length: 279 mm (11”)

Weight: 1.5 kg (3.3 lbs)

Muzzle velocity: approx. 76 m/s

Feed device: single-shot

Heckler & Koch L17A2 under-barrel grenade launcher (photo credit: UK MoD).

Heckler & Koch L123 series under-barrel grenade launcher. Note also the EOTech sight (photo credit: UK MoD).

Note: The information in this article has been superseded by that authored by Jonathan Ferguson & N.R. Jenzen-Jones and published in Jonathan Ferguson’s important original research work, Thorneycroft to SA80: British Bullpup Firearms, 1901–2020. That book is available from the Headstamp Publishing website: https://www.headstamppublishing.com/bullpup-rifle-book

Special thanks to the National Firearms Centre at the Royal Armouries, who graciously allowed us access to their world-class collection for this and other videos and photos.

This is Part 8 in a series of posts examining the developmental history of the United Kingdom’s SA80 family of small arms. Part 1 is available here, Part 2 is available here, Part 3 is available here, Part 4 is available here, and Part 5 is available here, Part 6 is available here, and Part 7 is available here.

Header image shows a British Soldier in Afghanistan firing an L85A2 fitted with an L123A2 under-barrel grenade launcher (photo credit: UK MoD).

Remember, all arms and munitions are dangerous. Treat all firearms as if they are loaded, and all munitions as if they are live, until you have personally confirmed otherwise. If you do not have specialist knowledge, never assume that arms or munitions are safe to handle until they have been inspected by a subject matter specialist. You should not approach, handle, move, operate, or modify arms and munitions unless explicitly trained to do so. If you encounter any unexploded ordnance (UXO) or explosive remnants of war (ERW), always remember the ‘ARMS’ acronym:

AVOID the area

RECORD all relevant information

MARK the area from a safe distance to warn others

SEEK assistance from the relevant authorities

8 thoughts on “British Enfield SA80 Part 8: Grenade Launchers”